LEGO Architecture meets BIM – Part 25: Making Waste Visible

Introduction

The posts in this series have been very focussed on the uses of the model that we created at the beginning of this series. These have all been very focussed to date on how technology can be used to support a BIM process. However in this post we look beyond the technology to consider how a BIM mindset can provide added value to projects.

This blog post is kindly written by guest blogger Simon Dean who is co-founder of PD BIM and Director of 3mu.

Making Waste Visible

Do you know people in the construction industry who fail to see the benefits of a BIM approach? However tempting it is to call these people out as dinosaurs should we instead consider whether the BIM process is letting them down? How can we engage the workforce – including BIM non-believers – in an industry which is striving to adopt BIM to improve its deliverables? We need to make the process inclusive, and must ensure we have a process that supports the production of work. What we need is a process that supports problem solvers, and I ask you how we go about doing this?

If your reaction to being gifted a new LEGO set is anything like mine, you eagerly open the box and proceed with the build, following the instruction manual until the project is complete.

Image: How do you tackle a LEGO build project?

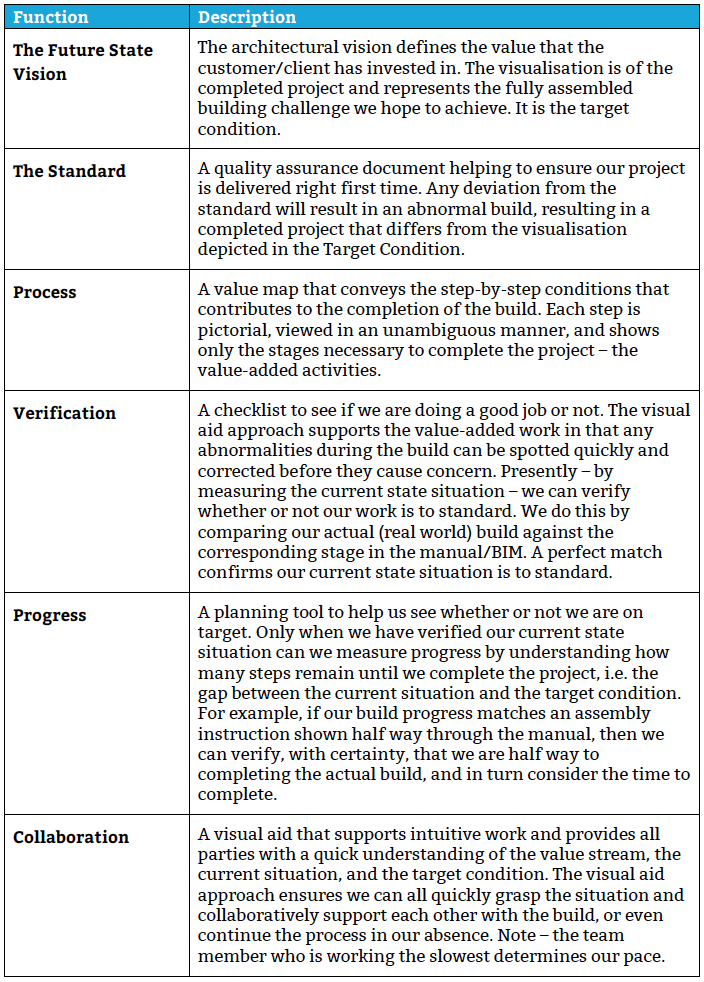

My technique is to carefully empty out a bag of components, shuffle the contents into an orderly fashion (of sorts) – so all the pieces to complete the next task are close to hand – and begin the build. My children adopt a different approach; tearing open the box with gusto to dive head-long into the project.

We can imagine our play time roles as being the equivalent of competing Tier 1 contractors, with each of us ensuring the build process is safe, on time and with an end result that matches the architectural vision (as depicted by the image on the box).

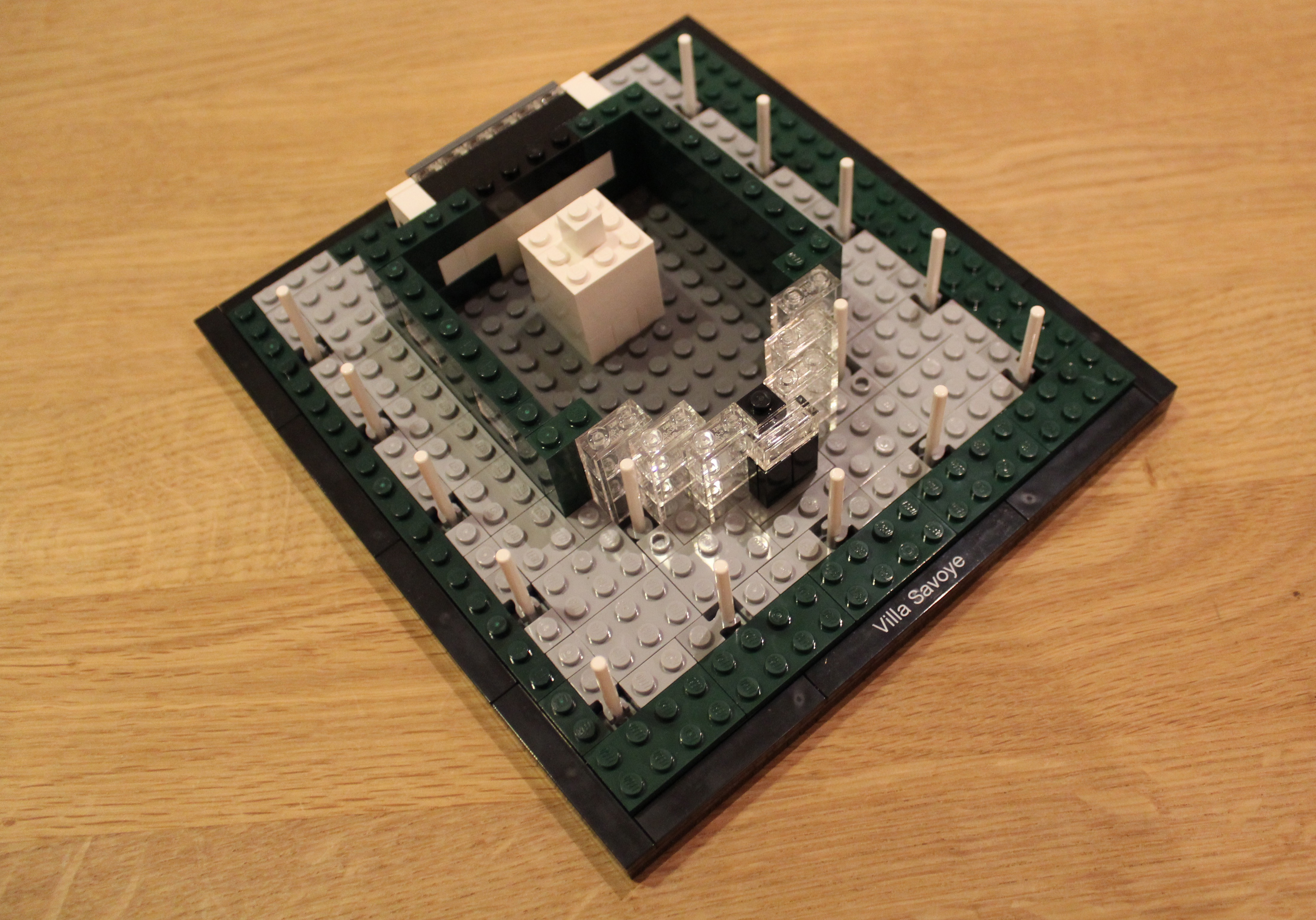

Image: The architectural vision of the construction project to be undertaken

I am confident that if we were to compare my build against those of my children the results would match in all areas except one: efficiency. Where due to my sausage-like fingers I struggle to fix a single tile into an intricate assembly arrangement, my children can proceed unobstructed due to their small hands and nimble fingers. Conversely, when my children’s progress is delayed with endless component searches under the bookshelf; a dining table; and the fridge(!), I can continue unhindered knowing that everything I require to complete the task is within easy reach.

If we were to consider the equivalent construction industry role for LEGO’s contribution to the build, we very quickly realise their generosity covers many responsibilities:

- The supply chain, providing only the necessary material – the building bricks – to complete the work;

- BIM support services, conveying only the necessary information – the instruction manual – to complete the work.

Image: The LEGO instruction manual for the Villa Savoye project

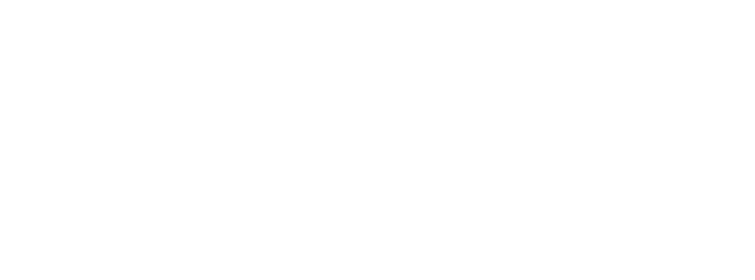

The LEGO instruction manual, like its BIM equivalent, is of fundamental importance and serves many support functions all of which are imperative in ensuring a successful project. Table 1 (below) lists how the instruction manual and BIM are used to visually support the work:

Table 1 [Click to enlarge]

To recap BIM can be used to:

- Demonstrate the ‘value’ as perceived by the customer – the target condition;

- Map the current condition to verify whether or not we are on target;

- Reveal any abnormalities that show if we have veered off course;

- Highlight the blockers that prevent us from reaching our target condition and;

- Facilitate collaboration in providing an intuitive grasp of the situation.

Using BIM this way is certain to bring benefits, even so the full advantages are unlikely to be met. This is because we are failing to consider the people and process which deliver the actual ‘valued’ work. Let me explain…

At the start of any LEGO build, in our role as Tier 1 contractor, each of us is faced with an infinite number of scenarios to complete the project. Using LEGO we often proceed straight to the build and it matters little if the progress is delayed with an impromptu hunt for mislaid bricks, or when clumsy hands inadvertently demolish a work-in-progress assembly; it is after all only play time, and besides there are no client or customer needs to satisfy other than our own.

Image: An infinite number of scenarios are possible with the pieces provided in the Villa Savoye set

I imagine it is with valid reasons the LEGO instruction manual does not depict the activities – the production line – between the value-added steps already illustrated. There is no such excuse however for the production line to be excluded from the BIM.

If at this point you’re thinking, “isn’t this 4D?” Yes it is, or it can be. Currently most 4D is used in a manner similar to the LEGO instruction manual, in that we simulate the value-added steps by giving visual emphasis to component items such as floor slabs, beams and columns. The problem for the construction industry with this approach is it provides little or no visibility for how the work is done, the impact on other silo operations and whether or not the work is efficient. The plan may work, but is it any good?

If BIM is to provide greater support to the construction industry in achieving its future targets – Digital Built Britain – we also have to consider how best we can use BIM as an intuitive visual management aid to make the production line visible. We therefore require a system that promotes the following:

A) Recognise that everything is a process which happens along a timeline;

B) Increase our understanding of the work by giving visibility to all silo types in order to support the delivery of value to the customer;

C) Give clear visibility of the ‘blockers’ so the effects of removing them can be tested and benefits proven before doing so.

For direction here I refer to a culture of learning that is proven to engage its workforce whilst striving to continuously improve the delivery of value to its customers: TPS (Toyota Production System).

“All we are doing is looking at the timeline…and we are reducing that time line by removing the non-value-added activities” [Taiichi Ohno]

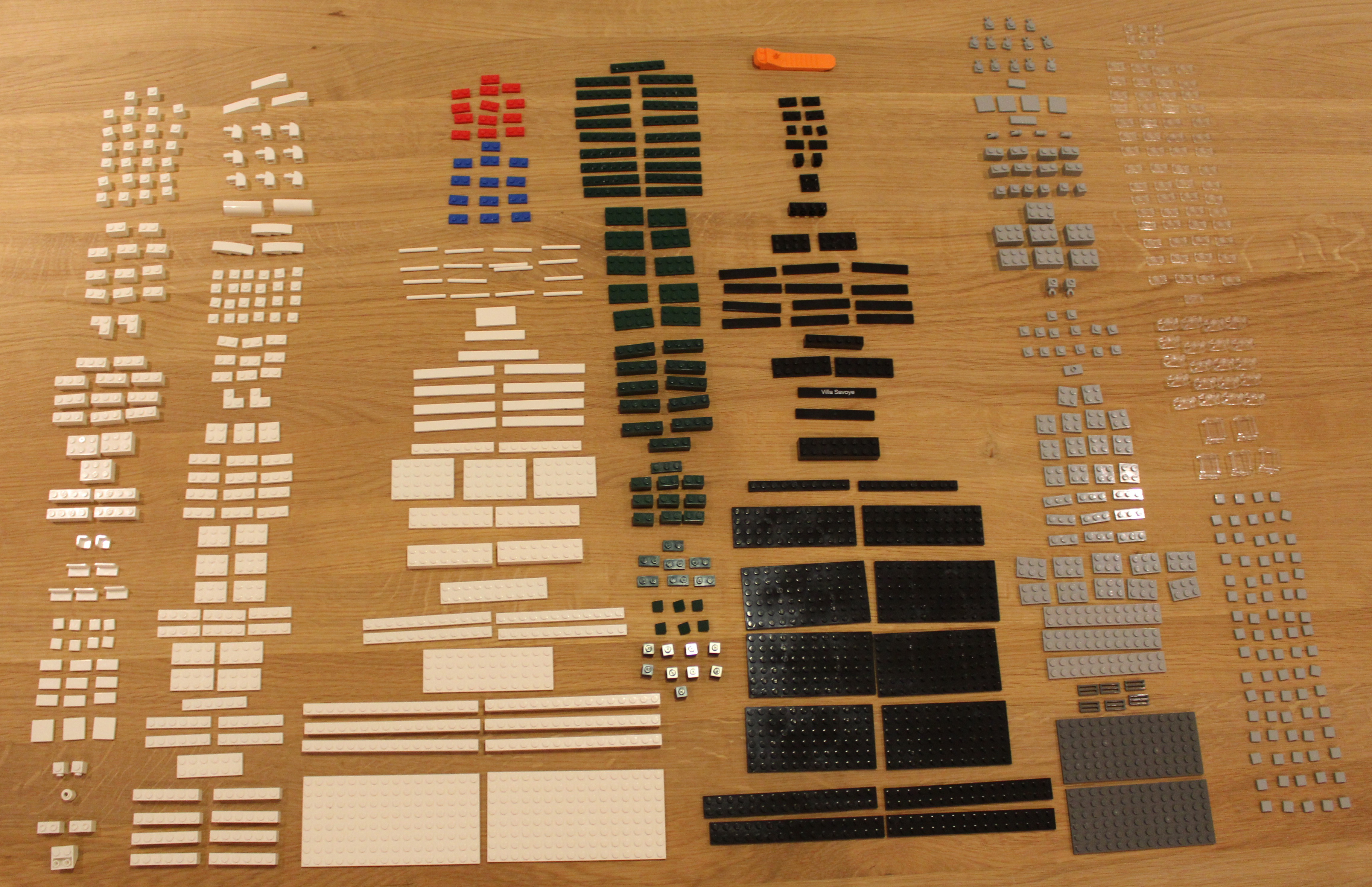

Throughout this post ‘value’ is defined as a successfully completed LEGO build identical to the visualisation on the box (see Table 1). Any action that contributes to a completed set – only those steps depicted in the manual – is considered a value-added activity. In contrast all other processes – those activities not depicted in the manual – must be, by their omission, non-value-added activities; whether essential or otherwise, even if we performed them for a hundred years or more.

TPS divides non-value-added activities into seven resources that are frequently wasted. These activities contribute to the ‘blockers’ that prevent us from achieving our target condition, as demonstrated in Table 2 (below):

Table 2 [Click to enlarge]

Table 2 (above) lists the resource activities that do not contribute to the value-added work. Only when these ‘wastes’ are made visible can we begin to measure and understand how much resource is afforded to non-value-added activities.

Quality & Safety are paramount. Reducing and/or eliminating ‘waste’ directly supports quality and safety.

For example, reducing excessive motion can reduce the risk of injury or fall by over-stretching. Each transportation activity increases the risk that products will be bumped, dropped or damaged. Inventory stock piles require real estate, security, additional planning and increases the risk that stored items may become damaged or even cause damage. Waiting activities can contribute to bottlenecks and downtime where they can lead to overburdened staff being rushed into making ill-considered decisions. Defects need replacement or repair; adding both time and cost to the programme, whilst likely redistributing resources from value-adding activities; an outcome of over-production.

Our focus up until now has been on the build, and our comparison with the construction industry limited to Tier 1 contractors, the supply chain and the production line assembly. I have demonstrated how by making the production line visible we can identify, map and reduce non-value-added activities. For the construction industry to fully benefit from BIM we must also consider how we best use visual management to support value-added activities, not only in the construction phase but throughout the entire project life-cycle.

Image: The construction phase in progress

Rushing to eliminate ‘waste’ in a single silo – the construction phase – without consideration for the entire project lifecycle has limited worth. At best the outcomes will be a more efficient way of doing the same old thing, at worst you may actual deteriorate the situation by changing the waste type into other forms (not covered here) in the same or other phases of the project. Using BIM we can make the production line visible across silos and fully engage the team as a single entity. This approach facilitates the workers to improve their own processes by designing a system which assigns resources only to value-added work.

Conclusion

Hopefully I have highlighted some of the important concepts relating to the model and how an inclusive approach which also considers the production line activities can produce better outcomes. Lastly, my comparison only considers the construction phase of the project with the added luxury that LEGO have resolved all the comparative construction industry project phases that lead up to the build. The LEGO R&D department have invested resources to ensure each product is safe, of quality and contains only the necessary components and information to complete a build which is perfect, every time. The same cannot be said for the construction industry. Yet.

Simon Dean, Co-founder, PD BIM and Director, 3mu Limited

Terms and conditions

All content provided on this BIM Blog is for informational purposes only. The owner of this blog makes no representations as to the accuracy or completeness of any information on this site or found by following any link on this site. Bond Bryan Architects will not be liable for any errors or omissions in this information nor for the availability of this information. Bond Bryan Architects will not be liable for any losses, injuries, or damages from the display or use of this information.

We are happy for others to share our blog pieces through all social media platforms. You may include links to the original blog pieces and use part of the blog to then provide a link to the original content. However we would appreciate it if the content is not reproduced in full on other sites or publications without written consent being granted by Bond Bryan Architects.

This policy is subject to change at any time.

LEGO and the Lego logo are trademarks of the LEGO Group. Any trademarks, service marks, product names, corporate names or named features are assumed to be the property of their respective owners, and are used only for reference, without intent to infringe.

![]()